Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Новости

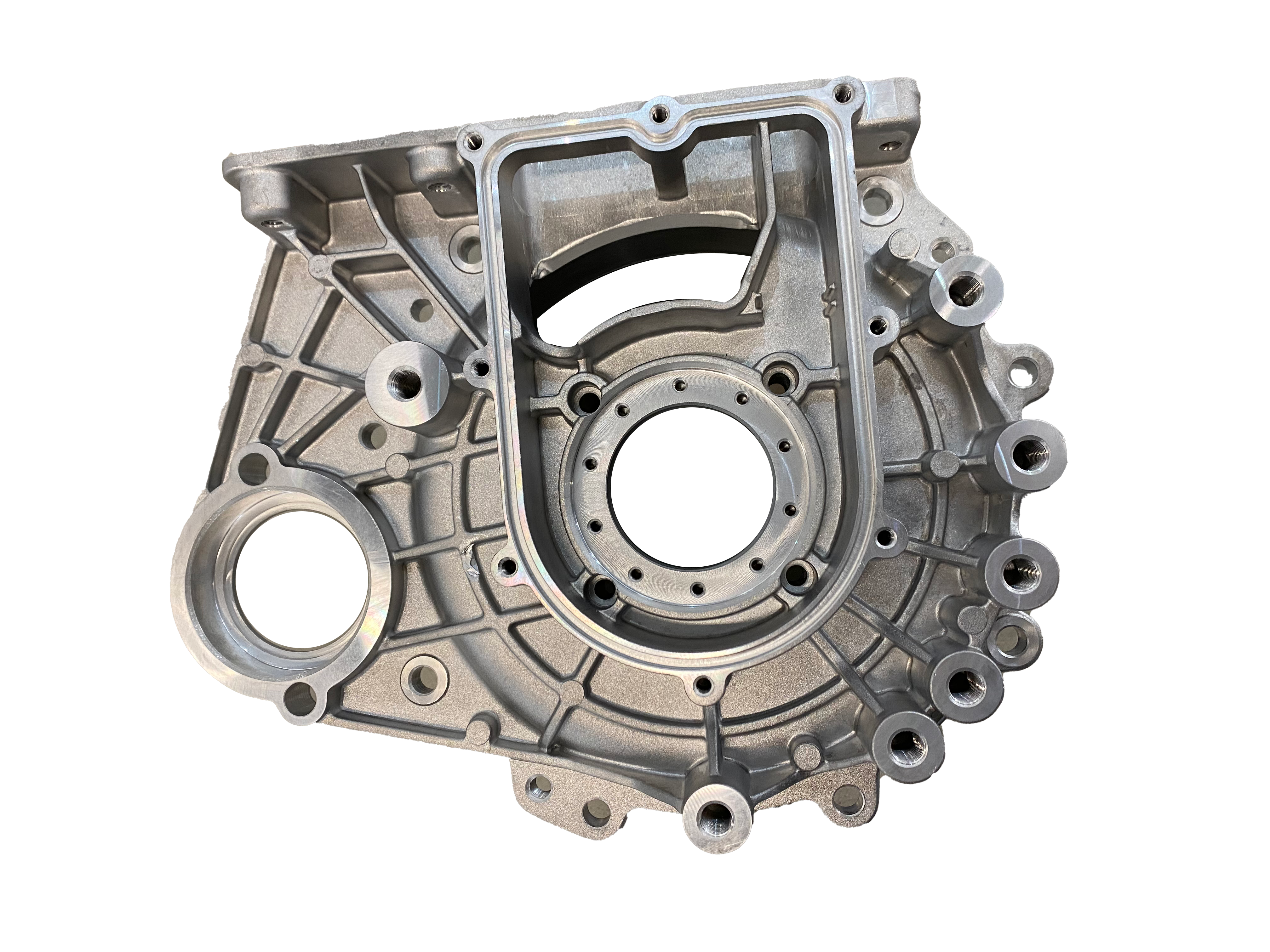

What You Need to Know about Die Casting Molds

Aluminum die-casting production is an indispensable die-casting mold, and the quality of the abrasive tool immediately endangers all the normal production of the company. A high-quality injection mold with a design scheme can maximize the productivity of machinery and equipment, reasonably reduce the electricity and energy costs of aluminum die-casting production, and reduce the failure rate of castings.

Several obvious problems of die-casting molds

Heat fatigue cracking destroys invalid

During the production of aluminum die-casting, the abrasive tool repeatedly receives the actual effect of stimulating cold and heat, and the internal deformation of the forming surface layer, and the two involve each other to show the welding stress of the repeated circulation system, resulting in the second damage of the distribution structure and the lack of patience, causing microscopic damage. The cracks show and continue to expand. Once the cracks expand, there will also be molten metal material squeezed in, and repeated mechanical stress will accelerate the expansion of the cracks. Therefore, on the one hand, the grinding tool must be sufficiently heated at the beginning of aluminum die casting. In addition, the abrasive tool must be maintained within a certain operating temperature range during the entire process of aluminum die-casting production to prevent early cracking. At the same time, it is necessary to ensure that the internal reasons before and during the production of the abrasive tool do not cause problems. In practical production, most abrasive tools are ineffective due to thermal fatigue cracking.

Break invalid

Under the actual effect of the injection force, the abrasive tool will sprout cracks at the most basic weak point, especially if the line imprints or metal processing imprints on the forming surface of the abrasive tool are not polished, or the formed face milling will initially show tiny Cracks when there is a ductile phase at the grain boundary or the crystal is thick, it is easy to crack. However, when ductile cracking occurs, the crack spreads rapidly, which is a very risky factor for the failure of abrasive tools. Therefore, on the one hand, all scratches and metal processing marks on the surface of the abrasive tool must be polished, and even if it is in the position of the pouring management system, it must be polished. In addition, it is stipulated that the applied abrasive material has high compressive strength, good plastic deformation, good impact resistance, and crack resistance.

Erosion is ineffective

Common aluminum die-casting aluminum alloys include zinc alloy materials, aluminum alloy profiles, die-cast aluminum, and alloy copper, and there is also pure aluminum alloy die-casting. Zn, Al, and Mg are more lifelike chemical elements, and they have a good infection with abrasive materials. The force is very Al easy to bite. When the strength of the abrasive tool is high, the corrosion resistance is good, and if there are soft spots on the forming surface, it is against the corrosive mildew.

How should the die casting mold meet the following requirements?

- Part of the posture of the abrasive tool theme activity in the whole process of the test piece should be flexible, stable, accurate, and reliable, whether there is tilt or stuck;

- The cooling water channel and gear oil channel should be unobstructed and watertight;

- The exhaust pipe of the abrasive tool is excellent, and whether the metal material liquid is splashed;

- Whether all the fixed parts of the abrasive tool are relatively shaken;

- The fitness movement of the guide rail slider should be stable, the guide rail slider and the wedge block should be clamped tightly after mold clamping, the total touching area should not be less than three-quarters, and the limit switch should be accurate and reliable after the mold is ejected;

- There is no sound from the ejector rod of the abrasive tool, and everything is normal when the ejector is returned;

- There is no abnormality in the follow-up of the punching needle, and there is no abnormality in the ejection of the product;

- There is no cracking, or deformation, and the fixed mold of the product part is removed from the mold;

- The basic inspection results of the specifications of the commodity parts after the abrasive tool is heated;

Conclusion

For more information about hot chamber die casting products, auto dies casting company,high pressure die casting aluminium alloys, we are glad to answer for you.