Ошибка формата электронной почты

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

Новости

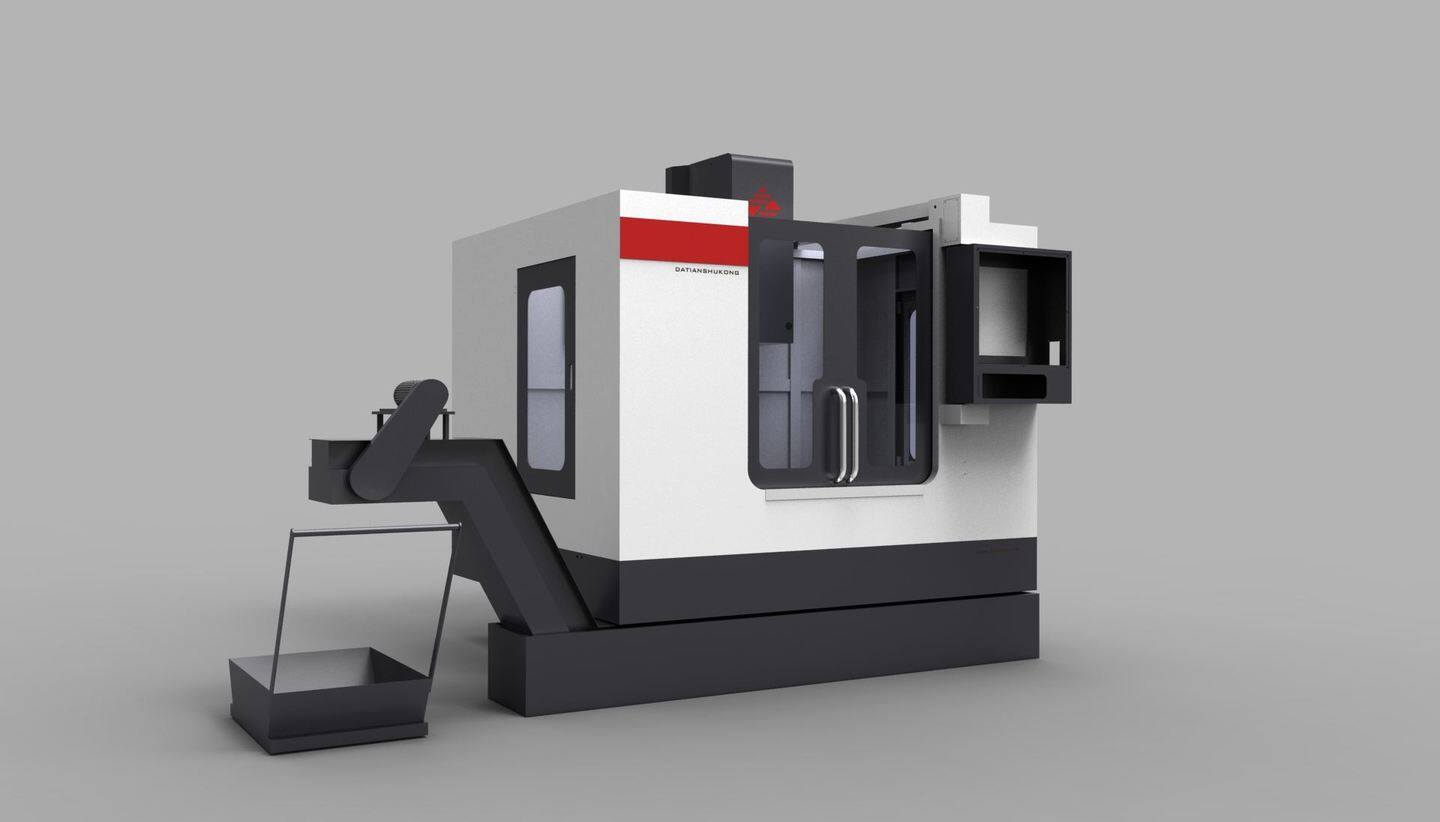

Future Development Direction of CNC Milling Machine

CNC milling machine is a milling machine controlled by the digital signal of the electronic meter. CNC milling machine is active processing equipment developed based on a general milling machine. The processing technology of a CNC milling machine is the same as that of a general milling machine, and its structure is also similar. There are two types of CNC milling machines with and without tool magazines. CNC milling machine with tool magazine is called machining center in machining profession.

A numerical control milling machine is a kind of numerical control machine tool with a strong processing function. Now the machining centers and flexible machining units that are rapidly developed are all based on numerical control milling machines and numerical control boring machines, and the processing methods of both are milling methods. Because the CNC milling process is very messy, and the technical problems that need to be dealt with are also the most, now people have always taken the milling process as the key point of research and development when discussing and developing the software of CNC systems and active programming language.

The machining surface shape of a CNC milling machine is generally composed of straight lines, arcs, or other curves. Generally, the milling machine operator shall follow the requirements of the drawing. Constantly changing the relative orientation between the tool and the workpiece, and then cooperating with the selected milling cutter speed, so that the tool can cut the workpiece, and then various workpieces of different shapes can be processed. The machining of the NC milling machine is to divide the motion coordinates of the tool and the workpiece into the minimum unit quantity, that is, the minimum displacement. According to the requirements of the workpiece program, the CNC system moves the coordinates by several minimum displacements and then completes the relative movement between the tool and the workpiece to complete the machining of parts.

With the process of industrialization and the rapid development of science and technology in China, mechanical products are becoming increasingly sophisticated and messy, and with the demand for frequent remodeling, especially in aerospace, shipbuilding, military, and other fields, the required mechanical parts have high precision requirements, messy shapes, and small batches. Processing such products often require refitting or adjusting equipment, and general machine tools or highly specialized automatic machine tools can no longer meet these requirements. The rapid development and wide application of CNC milling machines have solved the above problems. CNC milling machine has the advantages of strong adaptability, high machining accuracy, stable machining quality, and high production power. It summarizes and uses the technical achievements of electronic accounting machines, active control, servo drive, fine measurement, and new mechanical structure, which is the development direction of CNC machine tools in the future.

How to give full play to the advantages of a CNC milling machine?

First of all, because the CNC milling machine is electromechanical equipment, it is also relatively difficult to operate, especially the new equipment, which inevitably suffers from oscillation or quality problems of electronic components during transportation. After using it for some time, it will show shortcomings, and the root cause can not be found in the manual. It is suggested that the manufacturer pay attention to operation and repair training, constantly accumulate experience and constantly trek the general essence of the operators in the future application.

It is not necessary to strictly abide by the operating procedures and trek through the starting rate of the CNC milling machine. The operating procedures can not only ensure the safety of operators and equipment but also extend the application time of the equipment. If it is used for the first time or not used for a long time, idle it for a few minutes when starting it, and pay attention to the sequence of startup and shutdown. Beginners or operators with little experience should pay attention, After starting up, you should first use manual or program instructions to automatically return to the reference point; The newly purchased CNC milling machine should be used as much as possible, which will virtually increase the warranty cost, so try to expose the weak links within the warranty period, and even if there is no production task, it should be powered on on on time.

Searching for a best benchtop cnc milling machine, small 4 axis cnc milling machine, 7 axis cnc milling machine from China, you can get high-quality products at a nice price.